How to use carbon fiber tubes for RC planes can significantly improve your aircraft’s performance? Carbon fiber tubing is lightweight and strong, making it the preferred choice of many RC aircraft manufacturers.

1. What Are Carbon Fiber Tubes?

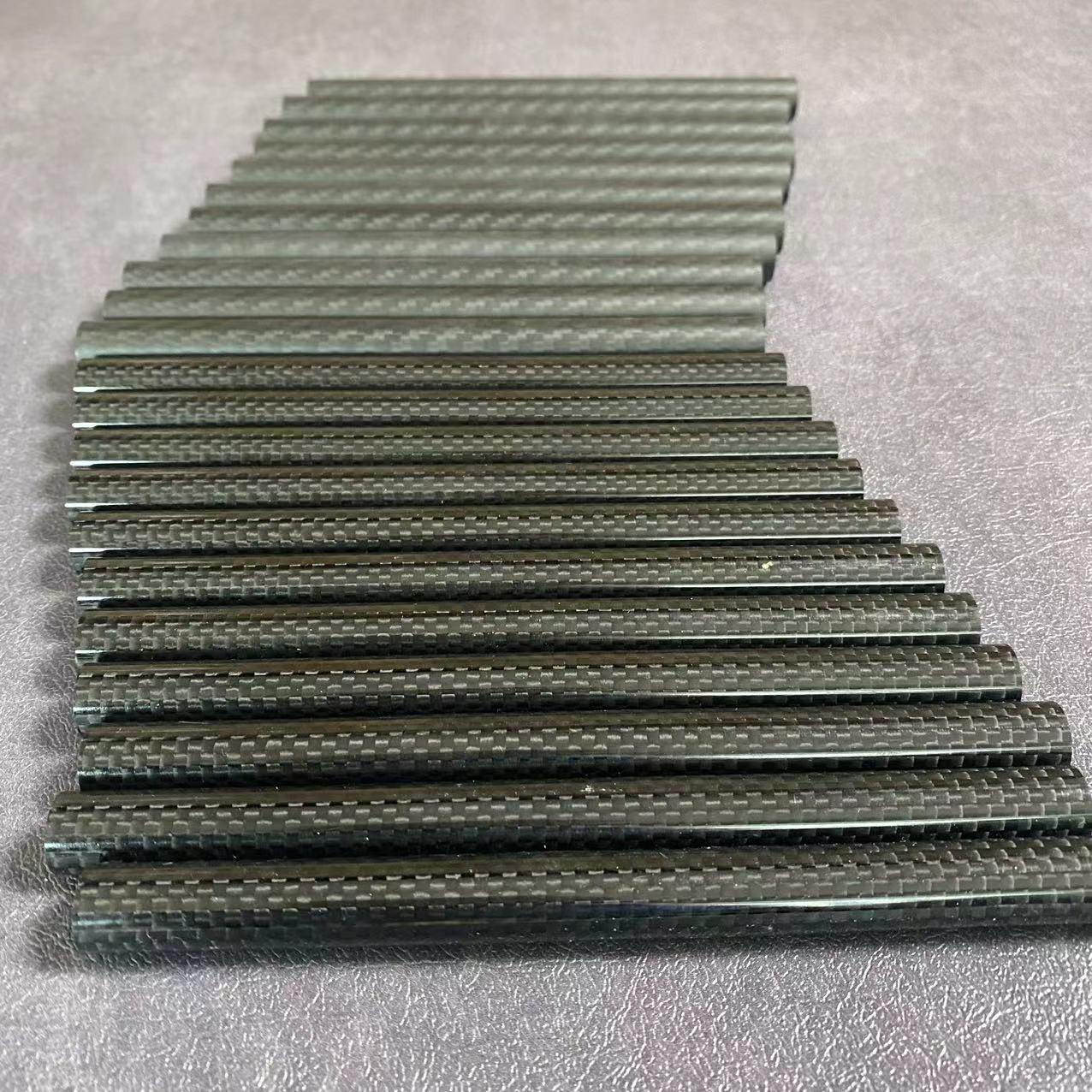

Tubes en fibre de carbone are hollow cylindrical structures made of carbon fiber, designed for applications that require a high strength-to-weight ratio. Carbon fiber itself is known for its light weight, high strength, and corrosion resistance, making it an ideal material for remotely piloted aircraft. These tubes are commonly used in the manufacture of aircraft fuselages, wing supports and structural components, providing maximum strength without adding unnecessary weight.

2. Advantages of Carbon Fiber Tubes for RC Planes

Lightweight Design

One of the outstanding features of carbon fiber tubing is its extremely light weight. For RC airplanes, reducing weight directly increases speed and maneuverability, resulting in a smoother and faster flying experience.

Haute résistance

Despite their light weight, carbon fiber tubes have excellent tensile strength and impact resistance. They are therefore ideally suited to withstand the stresses associated with high-speed flights and hard landings.

Durability and Longevity

Carbon fiber tubing is highly resistant to wear, fatigue and corrosion. This ensures a long service life for your RC airplane components, even during frequent flights or harsh conditions.

Customization and Flexibility

Carbon fiber tubing can be customized to a variety of diameters, lengths and wall thicknesses, making it versatile and suitable for a wide range of RC aircraft designs. Whether you’re building a high-performance racing aircraft or a slow-flying model, carbon fiber tubing will meet your needs.

3. Applications of Carbon Fiber Tubes in RC Planes

Tubes en fibre de carbone have various applications in RC plane manufacturing, and their primary uses include:

Airframe Construction

Carbon fiber tubing is commonly used to make frames for RC airplanes. Carbon fiber tubing is lightweight and strong, making it an ideal material for creating sturdy aerodynamic structures without adding excess weight.

Wing Spars and Support Structures

These tubes are commonly used to build wing struts and other support structures. Carbon fiber is strong and lightweight, making aircraft designs more robust and stable.

Battery Compartment and Other Components

In addition to structural components, carbon fiber tubes can be used to customize battery compartments, control surfaces and other specialized components for efficient use of space and weight distribution.

4. How to Choose the Right Carbon Fiber Tubes for Your RC Plane

When selecting carbon fiber tubes for RC planes, several factors should be taken into consideration:

Size and Weight

Choose the right diameter and length for your project. Make sure the tube is lightweight but strong enough to support the necessary parts of the RC airplane.

Wall Thickness

The wall thickness of carbon fiber tubing has a significant impact on its strength. Depending on the aircraft component, you may need different thicknesses of carbon fiber tubing to meet various structural requirements.

Customization Options

If your RC airplane has a unique design, look for a supplier that offers customization options. Custom carbon fiber tubes can ensure that they fit perfectly with your aircraft design and meet your exact specifications.

Quality and Brand

Carbon fiber tubes must be purchased from a reputable manufacturer. Ensure that the carbon fiber tubing meets industry standards for strength and durability to ensure the safety and performance of the aircraft.

5. How To Maintaining and Caring for Your Carbon Fiber Tubes

Although tubes en fibre de carbone are incredibly durable, proper maintenance is essential for maximizing their lifespan. Here are a few maintenance tips:

Regular Inspection

Periodically inspect carbon fiber tubes for cracks, dents, or signs of damage, especially after rough landings or high-impact activities.

Cleaning

Use a soft cloth to clean the carbon fiber tube. Avoid harsh chemicals that may damage the surface or affect the integrity of the material.

Avoid Over-Bending

Although carbon fiber tubes are strong, excessive bending can cause them to crack or break. When storing or transporting your RC aircraft, make sure that the carbon fiber tubing is not bent beyond its limits.

Ready to enhance your RC plane design with tubes en fibre de carbone sur mesure? Contact us today for tailored solutions and bulk order pricing. We’ll work with you to ensure your RC plane gets the high-quality components it deserves.